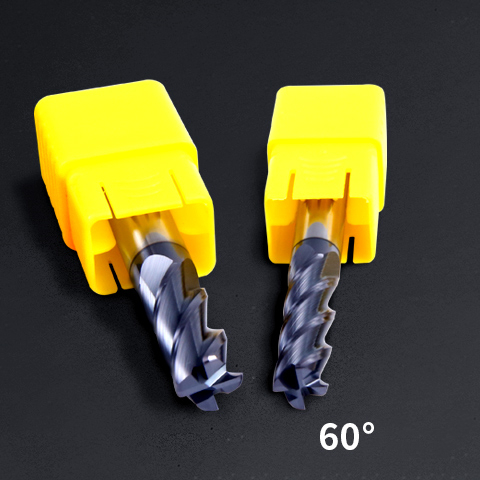

HRC 60 4 Flutes Corner rounding End Mill Radius Cutter

Ipharamitha Yomkhiqizo

| Uhlobo | HRC 60 4 Isigayo sokuphela sekhoneni leFlutes | Okubalulekile | Insimbi ye-Tungsten |

| I-Workpiece Material | Insimbi Yekhabhoni;Insimbi Yengxubevange;Insimbi Yokuphonsa;Insimbi Engagqwali;Insimbi Eqinile | Ukulawulwa Kwezinombolo | CNC |

| Iphakheji Yezokuthutha | Ibhokisi | Umtshingo | 4 |

| Ukugqoka | I-AlTiSiN | Ukuqina | HRC60 |

Isici

1.Sebenzisa i-nano-tech, ubulukhuni nokuzinza kwe-thermal kufika ku-4000HV kanye ne-1200 degree, ngokulandelanayo.

2. Idizayini enama-double-edge ithuthukisa ukuqina nokuqedwa kwengaphezulu ngempumelelo.Ukusika phakathi nendawo kunciphisa ukumelana nokusika.Umthamo ophezulu we-junk slot uzuzisa ukususwa kwe-chip futhi ukhuphula ukusebenza kahle kwemishini.

Imiyalo yokusetshenziswa

Ukuze uthole indawo engcono yokusika futhi welule impilo yamathuluzi.Qiniseka ukuthi usebenzisa ukunemba okuphezulu, ukuqina okuphezulu, nezibambi zamathuluzi ezilinganiselayo.

1. Ngaphambi kokusebenzisa leli thuluzi, sicela ulinganise ukuchezuka kwethuluzi.Uma ukunemba kokuchezuka kwethuluzi kudlula u-0.01mm, sicela ukulungise ngaphambi kokusika

2. Ubude bethuluzi bufushane ukusuka ku-chuck, bungcono.Uma ithuluzi eliphumayo lilide, sicela wehlise isivinini sokulwa, isivinini sokuphakelayo noma inani lokusika uwedwa

3. Uma ukudlidliza okungavamile noma umsindo kwenzeka ngesikhathi sokusika, sicela wehlise isivinini sokuphotha kanye nenani lokusika kuze kube yilapho isimo sesishintshile.

4. Izinto zensimbi zipholiswa ngesifutho noma indiza yomoya njengendlela esebenzayo yokwenza i-titanium ephezulu ye-aluminium ibe nomthelela omuhle.Kunconywa ukusebenzisa uketshezi lokusika olungancibiliki emanzini ngensimbi engagqwali, ingxubevange ye-titanium noma ingxubevange engashisi.

5. Indlela yokusika ithintwa i-workpiece, umshini, kanye nesofthiwe.Idatha engenhla ingeyereferensi.Ngemuva kokuthi isimo sokusika sizinzile, khulisa izinga lokudla ngo-30% -50%.

Sebenzisa

Kusetshenziswa kabanzi emikhakheni eminingi

Aviation Manufacturing

Ukukhiqizwa Kwemishini

Umkhiqizi wezimoto

Ukwenza isikhunta

Ukukhiqiza Ugesi

I-Lathe processing

Q1:Ngingathola isampula ukuze ngihlolwe?

A: Yebo, singasekela isampula.Isampula izokhokhiswa ngokufanelekile ngokusho kwezingxoxo phakathi kwethu.

Q2:Ngingakwazi ukwengeza uphawu lwami emabhokisini/amabhokisini?

A: Yebo, i-OEM ne-ODM kuyatholakala kithi.

Q3: Yiziphi izinzuzo zokuba umsabalalisi?

A: Isaphulelo esikhethekile Ukuvikelwa kokumaketha.

Q4:Ungayilawula kanjani ikhwalithi yemikhiqizo?

IMP: Yebo, sinonjiniyela abakulungele ukusiza amakhasimende anezinkinga zosekelo lobuchwepheshe, noma yiziphi izinkinga ezingase ziphakame phakathi nenqubo yokucaphuna noma yokufaka, kanye nokwesekwa kwe-aftermarket.100% uzihlole ngaphambi kokupakisha.

Q5:Ngingakwazi ukuvakashela imboni yakho ngaphambi kwe-oda?

A: Impela, siyakwamukela ukuvakasha kwakho kwefekthri.